Environment

We care about the environment: 20% of our annual consumption of electricity is produced by a solar power plant.

Our 300 KW PV power generating system guarantees a significant annual reduction of emissions into the atmosphere:

- Sulphur dioxide (SO2): -211 kg

- Nitrogen oxides (NOx): -131 kg

- Particulate matter: -6.6 kg

- Carbon dioxide (CO2): -157 t

(Calculation based on thermoelectric production equivalents)

Production and technology

Our company produces deep-drawn parts, manufactured according to our customers’ designs and specifications. The production process includes a wide range of processing activities, from flat blanking to deep drawing, including 2D/3D laser cutting.

Our particular expertise lies in the deep drawing process, in which we excel, developed as a result of the know-how acquired over 70 years of business.

READ MORE

Our particular expertise lies in the deep drawing process, in which we excel, developed as a result of the know-how acquired over 70 years of business.

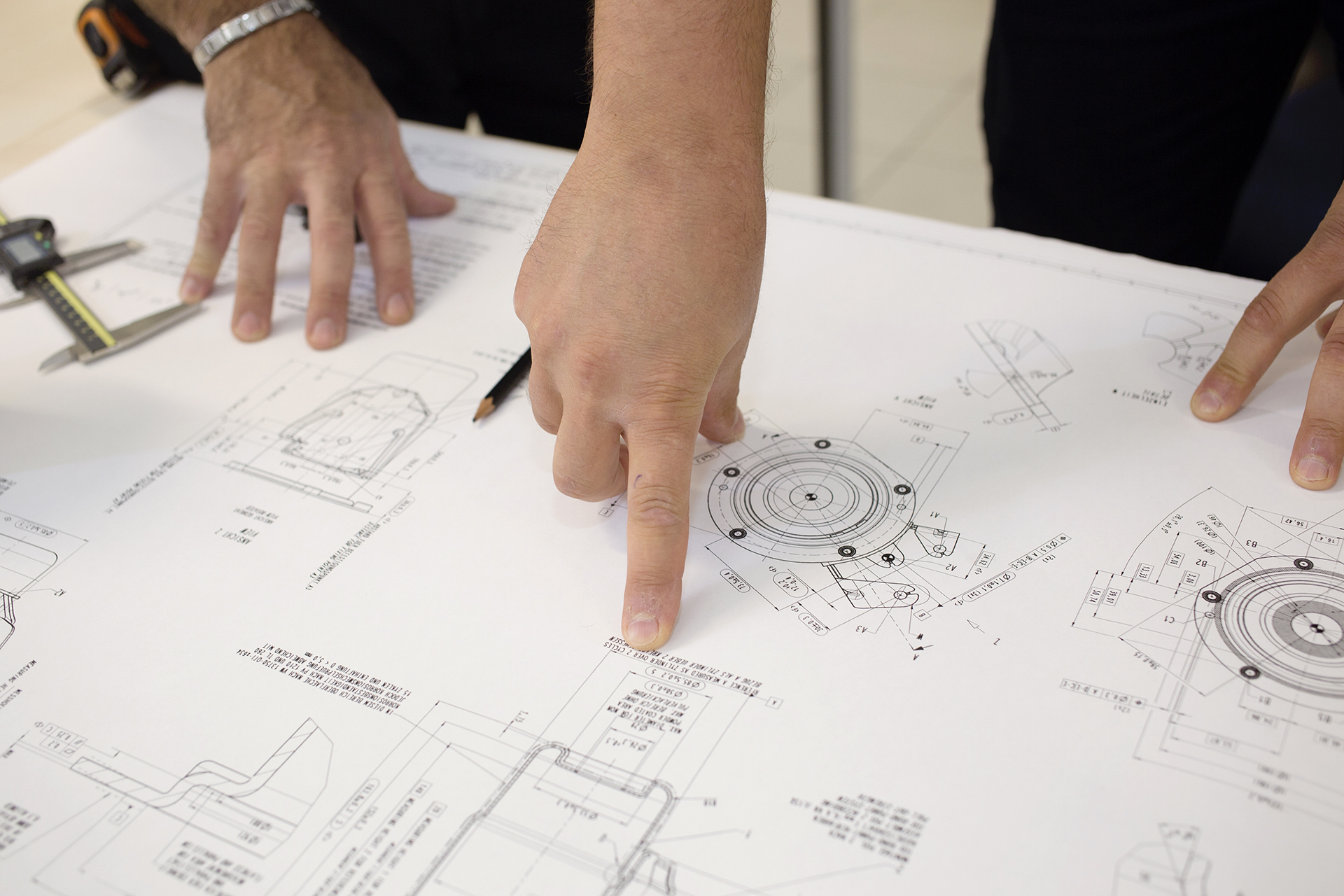

Design

We take special care of our customers’ requirements and expectations. Our commitment translates into the continuous search for the most effective technical and qualitative solutions for the development of new products.

Our technical department features the most innovative analysis, design and simulation equipment in order to support our customers with feasibility studies, co-design and the development of prototypes.

READ MORE

Our technical department features the most innovative analysis, design and simulation equipment in order to support our customers with feasibility studies, co-design and the development of prototypes.

Quality

To constantly improve customer satisfaction, we have adopted a Quality Management System that is certified in accordance with the ISO 9000 standards.

Continuous production checks are properly recorded in our databases for statistical evaluations.

The goals we pursue every day are:

• Ongoing improvement

• Product quality

• Punctuality and reliability

• Flexible production

• Technical expertise and professionalism

• Lean manufacturing

Download certificate

Download policy

Continuous production checks are properly recorded in our databases for statistical evaluations.

The goals we pursue every day are:

• Ongoing improvement

• Product quality

• Punctuality and reliability

• Flexible production

• Technical expertise and professionalism

• Lean manufacturing

OUR NUMBERS

70

years of history

8500

sqm covered area

10

million parts produced

59

presses

50

employees

6200

tons of sheet metal used yearly

10%

of turnover is re-invested in technology every year

900

hours of training per year

LONARDI CLAUDIO: SINCE 1949 IN THE STAMPING SECTOR

1949

the Lonardi family sets up the sheet metal stamping company

1980

transformation of the company into a joint-stock company

1992

Claudio’s son Pietro and daughter Silvia join the management team

1997

first automatic line for the production of oil filters

2002

relocation to the new 4500 m2 production plant

2003

implementation of a new automatic line for the production of diesel filters

2007

2000 m2 expansion of sheet metal warehouse and logistic reorganisation

2010

new mechanical presses up to 315t for progressive die stamping

2005

no. 3 automatic lines for car OE filter

2011

new automatic line for stamping of parts with height up to 400 mm

2012

new solar system to produce our own power

2013

new 2D/3D laser cutting system

2014

new 400 ton hydraulic press for stamping of parts with height up to 530 mm

2016

new line of hydraulic presses for high volumes

2017

new 2000 m2 warehouse for finished products

2018

new Multipress with 7 automatic stations for deep drawing and processing of complex parts

Created by Ebweb | Powered by SelfComposer CMS

Italiano

Italiano English

English Français

Français Deutsch

Deutsch Español

Español